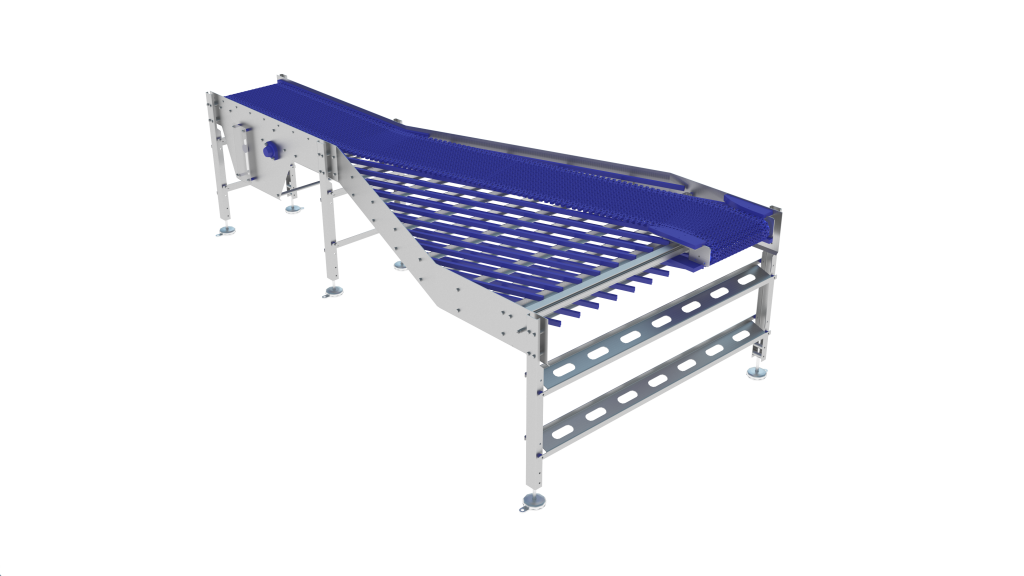

The JPFD Switch is designed for food-processing applications. The open design of the conveyor frame and the excellent and easy-to-clean hybrid belt are ideal for handling unpacked food products. The JPFD Switch has a modular setup and is available in various configurations. This allows you to configure the switch exactly to your needs. With the flexible setup, the JPFD Switch always fits your plant design.

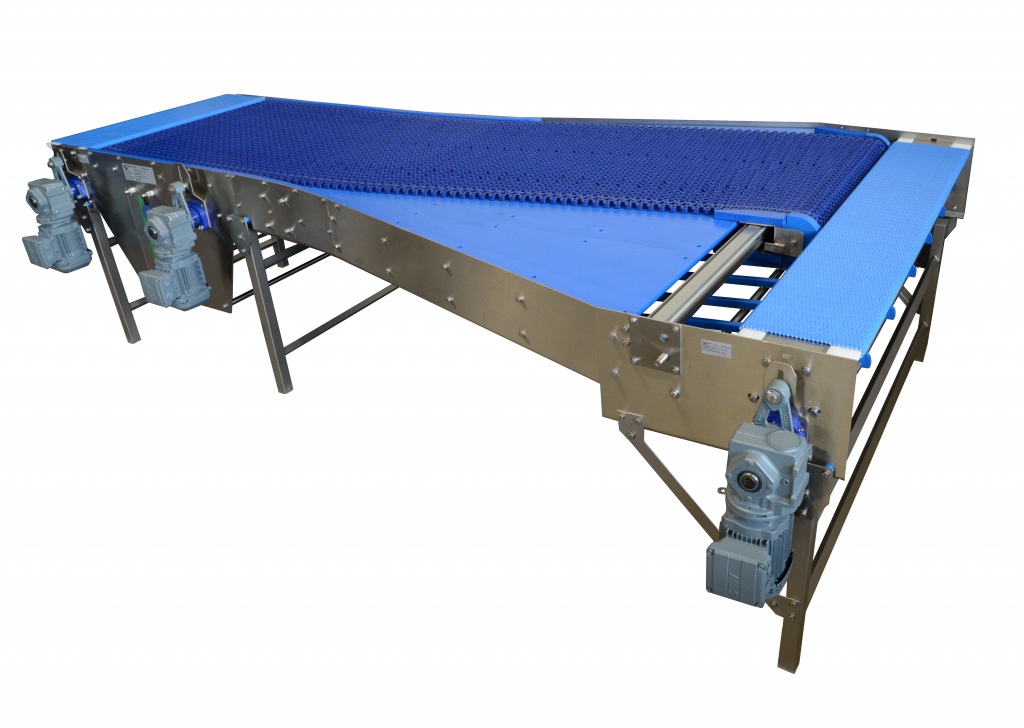

The open design of the JPFD Switch offers clear access for maintenance and washdown. This means reduced maintenance and cleaning costs and better sanitation.

The open double-slotted belt design prevents the trapping of food in the hinge area between the rod and the module. Due to the double-slotted links and open module design, the belt has superior sanitation characteristics.

The all-plastic contact surface ensures an excellent product release of unpacked food products such as poultry, meat, and fish. The open design allows for an exceptionally large open area (up to 67 percent when the belt is expanded).

The low cost of ownership is one of the main benefits of the JPFD Series. The rigid construction of the conveyor and the use of high-quality components and materials ensure a long lifetime and low maintenance costs.

JPFD Switch has a compact and floor space-saving design. With the JPFD 120 belt, the JPFD Switch fits into almost any plant design.

The flexible modular design makes it all possible if you want to go from 1 production line to multiple lines or from multiple lines to multiple lines. Contact us for more information and a suitable solution for your conveying needs.

| Belttype | JP FD 120 |

| Belt material | Panels, Acetal (POM) / Rods, Stainless-steel / Friction top, PA6 (Nylon) |

| Belt Pitch | 30 mm (1,2”) |

| Minimum belt width | 203 mm (8”) |

| Standard sprockets | Pitch diameter 96,2 mm |

| Frame material | Stainless steel |

| Belt support | Nolu-s (FDA approved) |

| Belt steering | Aircilinder |

| Belt speed | Up to 35 m/min |

| Temperature range | 4 – 80 Celsius |

| Maximum belt load | 50 kg |